The project focuses on the development of 100% bio-based and non-toxic polyurethane for end products in the textile and synthetic rubber industry. In this way, knowledge institutes and companies from the border region strengthen their leading position in the development and use of bio-based materials.

The production of biopolymers for commercial applications is increasing year after year. Also within the synthetic rubber and textile industry, the transition to bio-based materials has started. The textile sector, for example, wants to produce at least 20% of its products from bio-based materials by 2030. However, biopolymers for textile coatings and synthetic rubber (elastomers), such as polyurethane, are only available for a limited number of applications and are not fully bio-based.

At the moment, the average bio-based content of biopolymers for textile coatings and synthetic rubber systems is between 40-60%. The limited availability of commercial bio-based isocyanates and the difficulties to process new bio-based isocyanates on a small scale inhibits obtaining higher values.

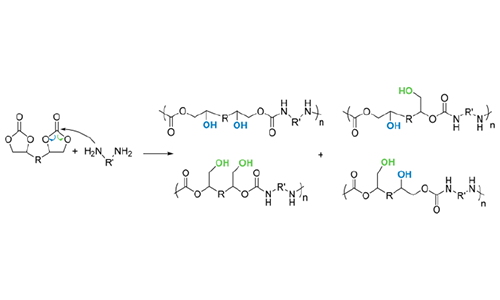

What is NIPU?

Non-isocyanate polyurethane (NIPU) is derived from the reaction between polycyclic carbonate and polyfunctional amines with primary amine groups. The result is a poly(hydroxyurethane) polymer with hydroxyl groups.

This not only avoids the use of isocyanates, but also permits possible further modifications of the hydroxyl groups. Possible applications include coating, adhesives, foams, sealants, and elastomers.

A truly sustainable route for polyurethane synthesis needs further research and an innovative approach, without using the traditional isocyanate and polyol chemistry.

The Bio NIPU project therefore focuses on research into alternative, non-toxic building blocks for the synthesis of polyurethane. Fully renewable raw materials - such as waste streams from sugar refining and the production of bio-diesel and natural oils and fats - are used to develop bio-based polyurethanes.